Load machines in test benches for electric motors to be used in the automotive sector, shipbuilding or industry must be powerful yet compact, lightweight and low-maintenance. Most importantly, they have to be as quiet as possible. On our test benches for testing standard specifications and customer requirements, we use water-cooled motors designed to meet the following requirements:

Quiet

Thanks to its water jacket and the absence of a fan, a water-cooled motor is many times quieter than an air-cooled motor. Permanent noise exposure from fan-cooled motors would not be tolerable for people working on test benches. The test environment also needs to be quiet in order to conduct certain noise and vibration measurements.

Low maintenance

Water-cooled motors require little in the way of servicing and maintenance. The thermal balance of fan-cooled motors deteriorates due to adhering dust and dirt particles, making regular cleaning necessary. However, dust adhesion is not a problem for water-cooled motors, as the temperature is dissipated via the inner water jacket. The low maintenance requirements also mean less downtime, and therefore lower costs. This is particularly beneficial for test benches that are subject to intensive use, such as those in the automotive industry, which may be in use 24/7.

Compact

As space is often at a premium in test benches, a water-cooled motor is a real asset with its compact installation dimensions and low weight, thanks to its smaller size and fewer components. The lack of a fan also frees up a lot of space.

Powerful

Both the performance and the efficiency of a water-cooled motor are generally higher than those of an air-cooled motor of the same size. A smaller-sized water-cooled motor can be used to achieve the same performance as a fan-cooled system. What’s more, the water-cooled motor is not exposed to such high thermal loads. The advantage of this is that it emits hardly any waste heat into the test room, which could falsify the results of a test specimen. Even under full load, our water-cooled systems only achieve a maximum surface temperature of 35°C on the test bench.

Ensuring cooling

Using a water-cooled motor requires a separate cooling unit, including pipework. The costs of this are generally reasonable. Alternatively, existing cooling or hydraulic systems may be repurposed in some environments, with the water-cooled motor integrated into the pipework. In this case, oil can be used instead of water as the cooling medium in hydraulic systems.

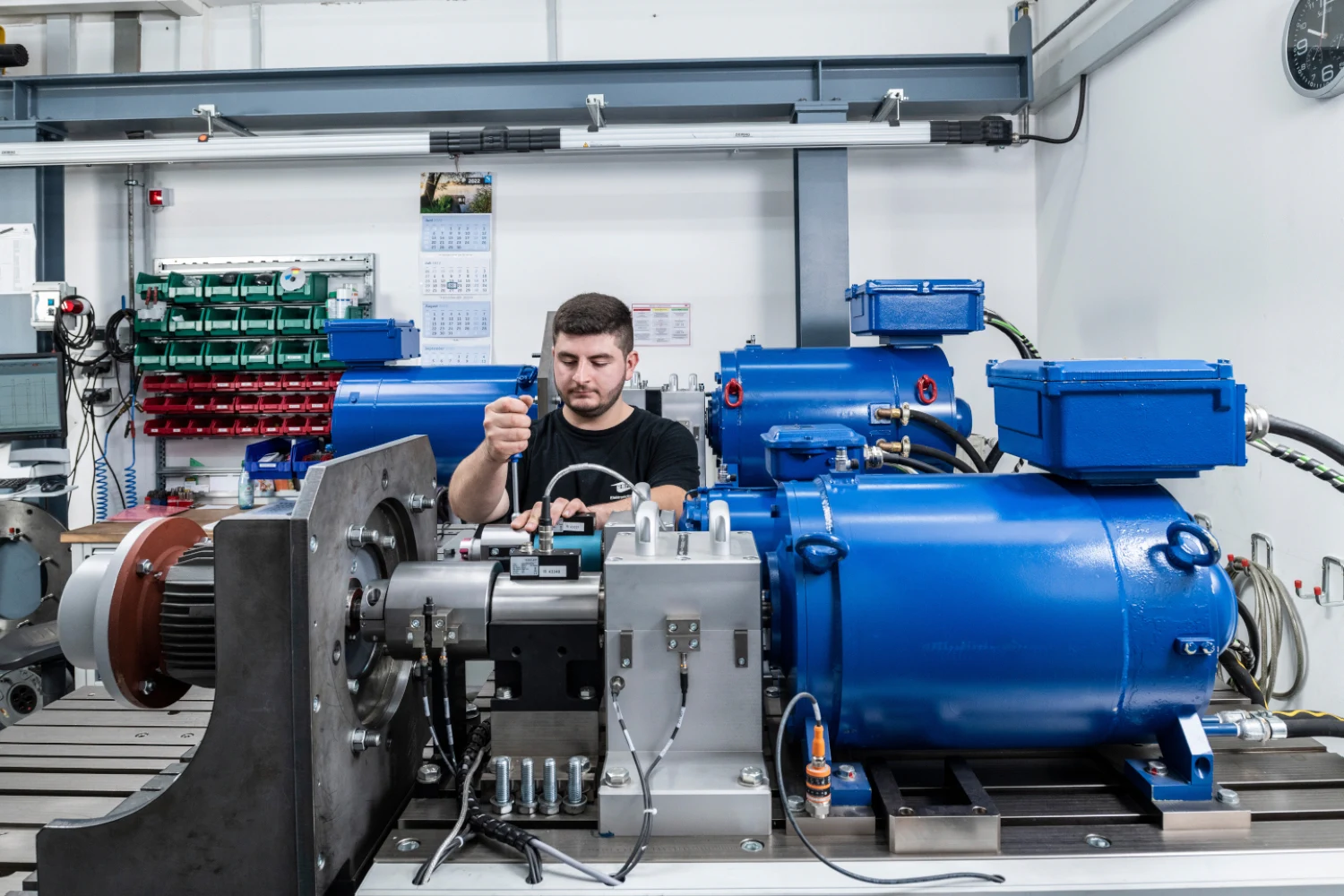

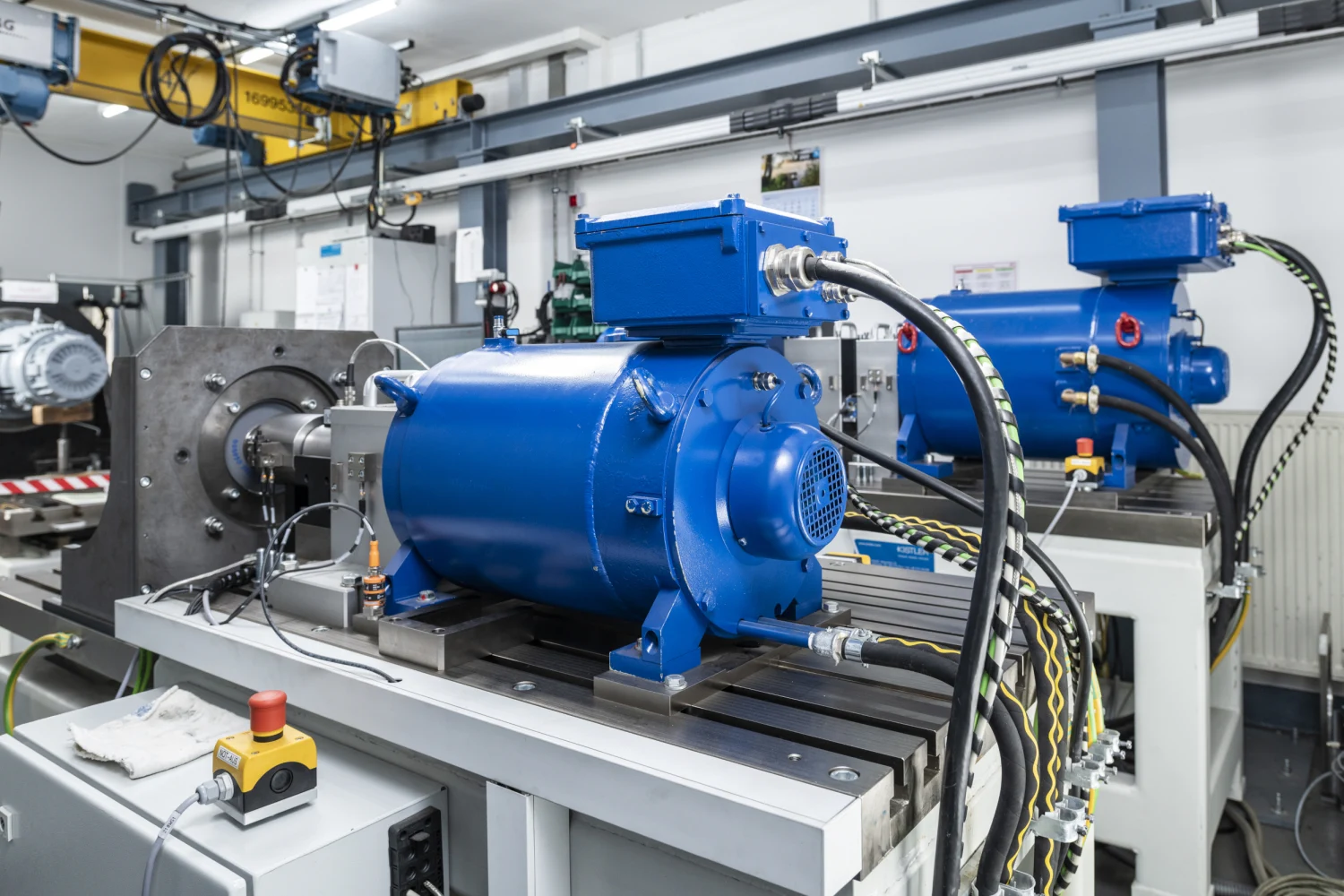

View of our test facility: three-phase synchronous and asynchronous motors with a mechanical output of 0.1 kW to 300 kW can be tested on the three test benches here. In the background: two water-cooled motors, one as a test specimen and the other as a load machine.