The ever-greater demands on the energy efficiency of IE4 electric motors – currently the highest energy efficiency class in accordance with DIN-EN 60034-30-1 – are pushing asynchronous machines to the limits of what they can physically do. There is a demand for alternatives that offer high efficiency and compact dimensions.

As part of a research project in conjunction with the Institute for Power Electronic Systems (ELSYS) at Nuremberg University of Applied Sciences, we are currently developing a synchronous reluctance machine for precisely these requirements. The aim was to devise a drive system for a cross-flow air blower for airstream simulation tests in automotive test benches. The previous size-160 system provided a blow velocity of 160 km/h. For the new system, this was to be increased to 180 km/h without enlarging the motor, due to the limited space available. It also needed to comply with energy efficiency category IE4.

Better efficiency, lower losses

Asynchronous machines can only fulfil the stringent efficiency requirements by stepping up development work and increasing costs. This prompted the idea of a synchronous reluctance machine. Such technology is not new, but for years it had been seen as somewhat inferior due to the lack of mains start-up capability and the need for an inverter. This project plays to its advantages.

The focus is on its superior efficiency compared to an asynchronous system, as only low losses occur in the rotor. A synchronised reluctance system operates on the basis of reluctance. It always strives for the lowest magnetic resistance (reluctance), triggering rotary movement. While the rotor of the asynchronous system runs asynchronously to the rotating field of the stator, the rotor of a synchronous reluctance machine rotates synchronously to the stator’s magnetic field. As a result, there are hardly any remagnetisation losses, which is highly advantageous for achieving IE4.

Promising prototype test results

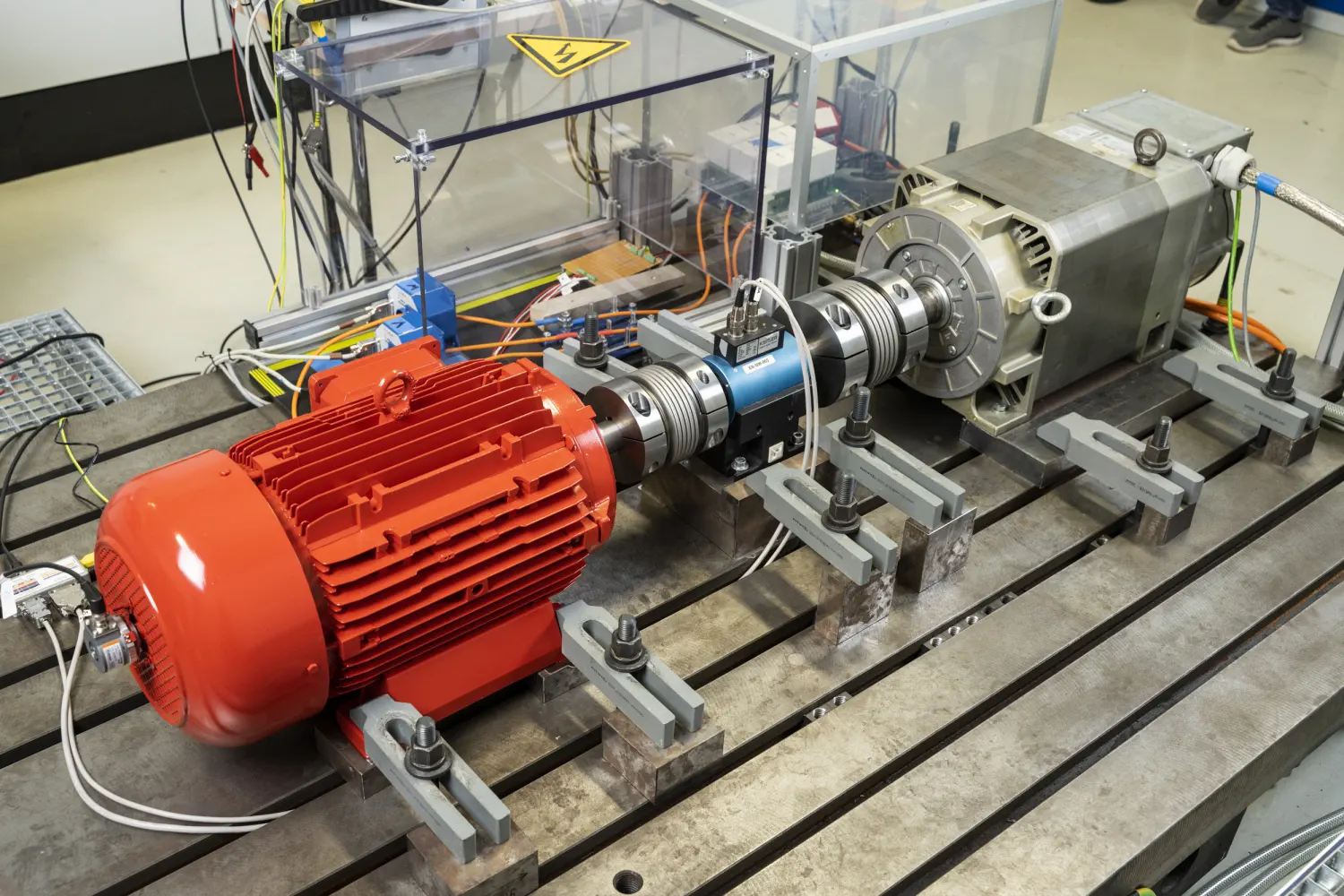

The prototype for the synchronous reluctance motor is currently being put through its paces on the university’s test bench. So far, the results of testing have been very promising, with the intended efficiency, rated points, torque and speed all achieved. This gives us great confidence for future drive projects with synchronised reluctance systems.

Synchronous reluctance systems are suitable for applications that require high efficiency combined with compact size in S1 operations. Potential applications include pumps, compressors, turbines and fans.

The individual rotor plates of a synchronised reluctance system have a special sheet-cut geometry consisting of flow conduits and flow barriers, which generate rotary motion.